ADAS Testing

Advanced Driver Assistance Systems

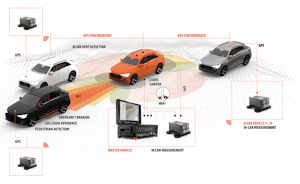

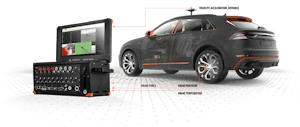

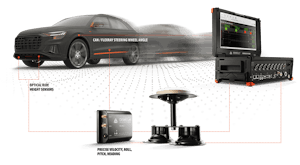

Dewesoft provides a turn-jet solution for ADAS testing with highly accurate inertial navigation systems (INS) to accurately measure relative positions and velocity between multiple moving and static objects.

All modern vehicles are now being equipped with Advanced Driver Assistance Systems (ADAS). The development of such systems requires complex testing, including the ability to control and calculate relative positions between multiple vehicles and objects in real-time.

![Power Analyzer - High-precision electricl power measurement and analysis [AC⚡DC]](https://www.datocms-assets.com/53444/1657614458-dewesoft-power-analyzer.png?auto=format&w=500?auto=format&w=300)