Temperature Recording

Thermocouple, RTD, and thermistor data recording

Factories run on machines, and it’s imperative that they operate at top efficiency. Avoiding unexpected breakdowns is critical. This is why you will find Dewesoft’s flexible and robust DAQ systems in use in every kind of manufacturing facility. Whether you’re monitoring one machine or a whole factory, our EtherCAT interconnected systems are there. We’re compatible with IIoT and industry 4.0 interfaces such as OPC UA, Siemens S7, EtherCAT, and others, seamlessly connecting to your existing ERP, SCADA, and Industry 4.0 infrastructure. Cloud-based monitoring allows easy data access and monitoring from anywhere. Companies like ABB, Caterpillar, Airbus, Boeing, Honeywell, and Nissan rely on Dewesoft.

Browse products

Thermocouple, RTD, and thermistor data recording

Voltage and high-voltage data recording

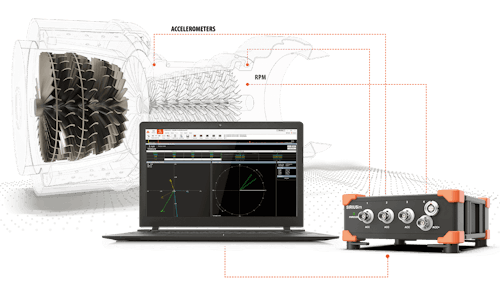

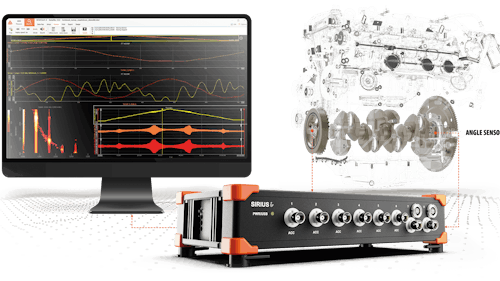

Rotor movements examination and assessment

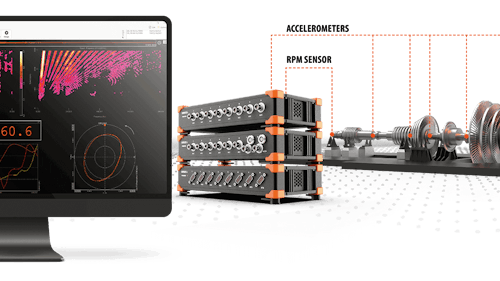

Noise and vibration analysis for rotating and reciprocating machinery

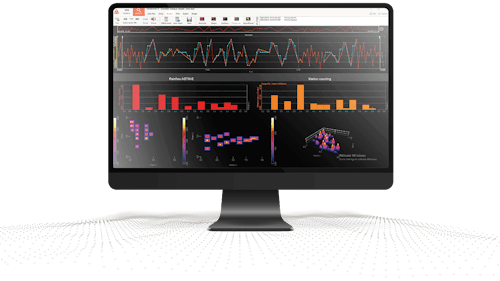

Static and Dynamic Balancing of Rotating Machinery

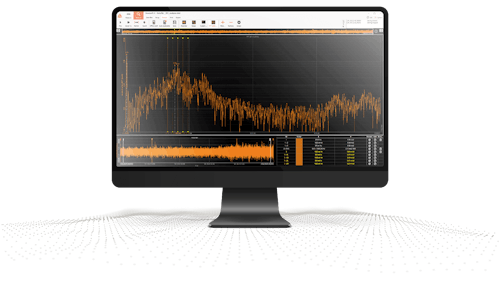

Vibration analysis to detect and diagnose faults in bearings and gears

Vibration and frequency analysis with a Fast Fourier transform

Class 1 Sound Level Meter for Sound and Noise Level Measurement

Octave band frequency analysis solution for sound and noise

Sound intensity level solution fully compliant with ISO standards

Sound power level measurement solution according to ISO standards

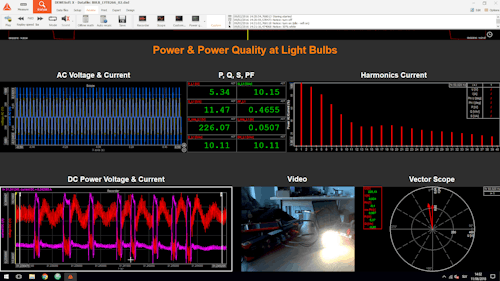

Complete power analysis and power quality testing solution

Vibration monitoring for gearboxes, fans, motors, pumps, etc.

Measure angular vibration of the rotating shafts

High-precision electrical power measurement and analysis [AC⚡DC]

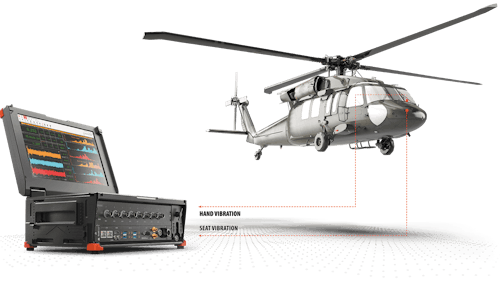

Whole-body and hand-arm vibration measurement

Winter and desert testing in extreme environment

And Fatigue Analysis

Data Acquisition Knowledge Base

End-of-line testing is the final quality gate in manufacturing, verifying that fully assembled products meet performance, safety, and regulatory requirements before shipment. Using automated test equipment, sensors, and data acquisition systems, EOL testing simulates real operating conditions, detects hidden defects, ensures traceability, and provides actionable data that improves reliability, reduces recalls, and supports continuous process improvement across industries.

Case Studies

In this article, you will learn more about lift capacity measurement. Using Dewesoft solution, Doosan Bobcat was able to acquire live data of a lift point.

Case Studies

At a German cast iron plant, engineers from Accon GmbH used Dewesoft vibration monitoring to identify machinery causing excessive ground vibrations that disturbed nearby residents. By analyzing data from key production units, they traced critical low-frequency sources such as shakeout machines and conveyors, then recommended isolation and equipment adjustments to reduce vibration emissions.

Application Notes

This application note showcases a proof-of-concept robotic arm system using Dewesoft’s IOLITE R8 hardware and DewesoftX software to simplify servo control. The setup combines real-time control, high-resolution output, and intuitive automation, demonstrating precise motion control, synchronized data acquisition, and easy integration with third-party systems.

Case Studies

Learn how the Dewesoft DAQ system has simplified the daily work of LOGICDATA, which develops mechatronic system solutions for adjustable furniture.

Case Studies

An international ice cream manufacturer partnered with Dewesoft to enhance their ice cream cone production line by improving the chocolate spraying process and automating production while maintaining quality standards. Using infrared cameras and data analysis, they monitored and analyzed the process.

Case Studies

A Dewesoft brake test system has helped BEML Ltd. to measure the brake performance on heavy machinery and verify them against international standards.

Case Studies

See how the Dewesoft sound intensity solutions and data acquisition system helped to do the automated measurement of the sound intensity on Bobcat loaders.

Application Notes

Reducing the output of carbon emissions is one of the most critical responses to climate change. Learn how Dewesoft DAQ helps in the field of supervision.

Case Studies

Learn how Dewesoft customer performed vibration analysis at the resonance attachment points inside a MRI scanner laboratory. Read the case study.

Application Notes

By installing the Dewesoft Machine Condition Monitoring solution paper mills get a reliable solution to detect bearing issues for its press section rolls.

Case Studies

NorraTimber has some issues in the final packaging process of the finished timber. Learn how they solved the problem using Dewesoft measurement solutions.

Case Studies

Dewesoft data acquisition systems are used to measure diesel generators for ISO 8528-1:2005 certification standards for sound, vibration, and temperature.

Case Studies

See how Dewesoft USA responded quickly and provided flexible data acquisition systems to set up an emergency ventilator production line to help hospitals.

Case Studies

Learn how Dewesoft's data acquisition systems with CAN bus interface provide an effective solution for scaffolding test and scaffolding safety approval.

Case Studies

Learn how BSH is utilizing our DAQ systems for voltage, current, and temperature measurements to test household appliances and perform power analysis.