Electric Vehicle Testing

Complete testing solutions for electric and hybrid vehicles

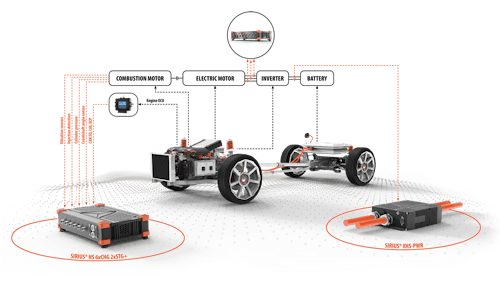

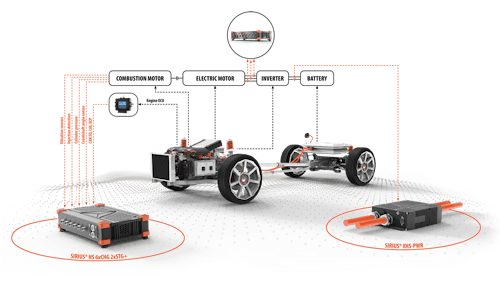

Electrification of vehicles is advancing rapidly. Dewesoft is the one-stop-shop covering core attributes like performance, efficiency, noise, vibration, thermal integrity and structural durability in lab and field with a single eco system and software. This allows a multi-path approach with e-axle, e-drive, inverter, fuel cell, battery, charger, and hybrid drivetrains with combustion engine (ICE).

Dewesoft provides advanced measurement and software solutions for testing tomorrow’s electrified drivetrains. Our technology supports high-bandwidth, time-synchronized analysis and recording across key vehicle buses. We specialize in electric power, torque and speed, NVH, and multi-physics applications. With remote control, EtherCAT integration, and support for both bench and end-of-line (EOL) testing, our tools are ideal for modern development and production environments.

Fast. Precise. Future-Ready.

Browse products

Complete testing solutions for electric and hybrid vehicles

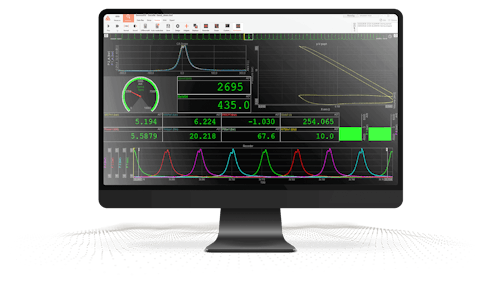

High-precision electrical power measurement and analysis [AC⚡DC]

Power and efficiency testing of electric motor and inverter

High-precision measurement and data analysis

Internal Combustion Engine Testing Solutions

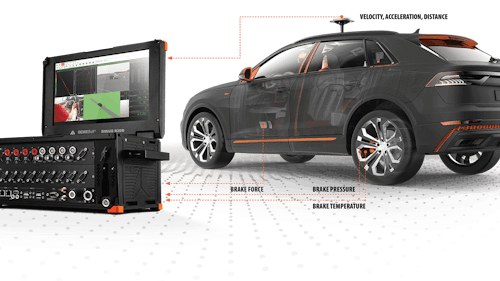

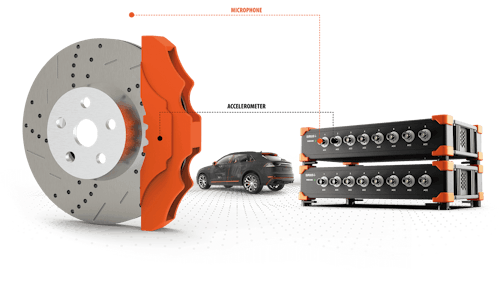

Vehicle brake and ABS testing (ISO, ECE, SAE, FMSSV)

Detect and track brake noise according to VDA 303 guideline

Winter and desert testing in extreme environment

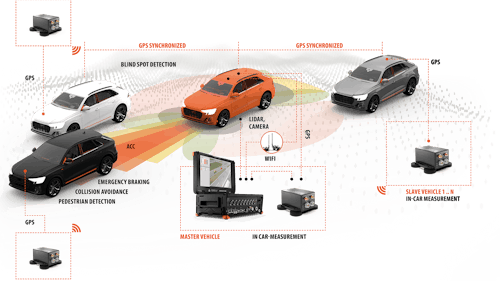

Advanced Driver Assistance Systems

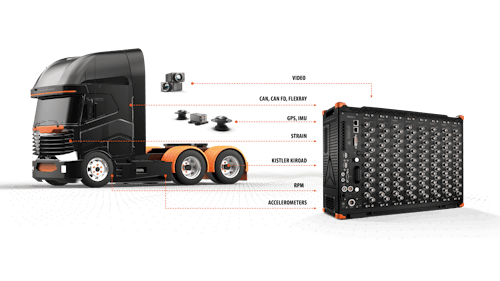

Road load data acquisition and analysis (RLDA)

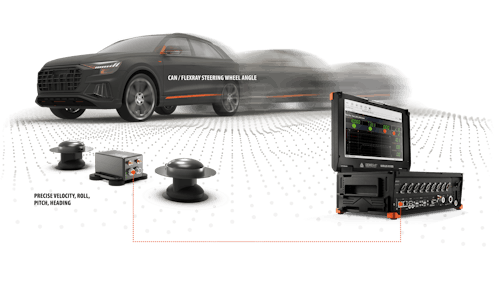

Ride dynamics based on ISO and ECE standards

Case Studies

The article explores load angle measurement in synchronous machines using an incremental encoder and DewesoftX software. Students at HTL BULME conduct lab exercises to analyze rotor position and phase shifts. Using Dewesoft SIRIUS devices, they gain hands-on experience in synchronization and machine behavior. Future work will expand calculations with the Dewesoft Motor Analysis plugin.

Case Studies

E-Team Squadra Corse from the University of Pisa successfully converted their Formula SAE car, E-VA, to an electric powertrain in 2023. Partnering with Dewesoft, they used advanced sensors and extensive testing in Siena to optimize performance, resolve electrical issues, and validate their models, enhancing the car’s reliability and paving the way for future electric vehicle developments.

Case Studies

Learn how Dewesoft DAQ systems and sensors were used to evaluate the energy needed to run electric minibuses at different speeds and loads in Mexico City.

Application Notes

Dewesoft has been actively working to provide flexible and powerful measurement systems specially designed for electric and hybrid drivetrains.

Case Studies

Learn how a Dewesoft DAQ system has helped Melecs with automated testing and provided a flexible solution for electrical testing of automotive components.

Application Notes

With the Dewesoft DAQ system, we decided to compare the capabilities of two motocross bikes - combustion and the electric one. Find out which is better!

Application Notes

In the process of electric vehicle development, producers need to perform energy flow analysis on vehicles under development for best economic performance.

Application Notes

See how to analyze the energy consumption of the electric motorcycle (electric motorbike) under real-life driving conditions using Dewesoft Power Analyzer.

Application Notes

In this article, you will find out about the influence of shielded cables on electric and hybrid vehicles under real-drive test measurement and analysis.

Case Studies

Learn how Dewesoft DAQ vibration enabled Elaphe to address the NVH issues and to evaluate and eliminate powertrain contributions to the cabin noise.

Case Studies

Dewesoft set up the measurement of both the DC and the AC part of the Q2 powertrain to measure the efficiency and quality of power conversion of the brushless motor power inverter.

Case Studies

Dewesoft power analyzer & data acquisition system was used for performance testing and measurement of Alfastreet Marine electric boat. See the case study.

Case Studies

Learn how the automation of the report generation process provided to be a huge time-saver after acquiring data with Dewesoft measurement equipment.